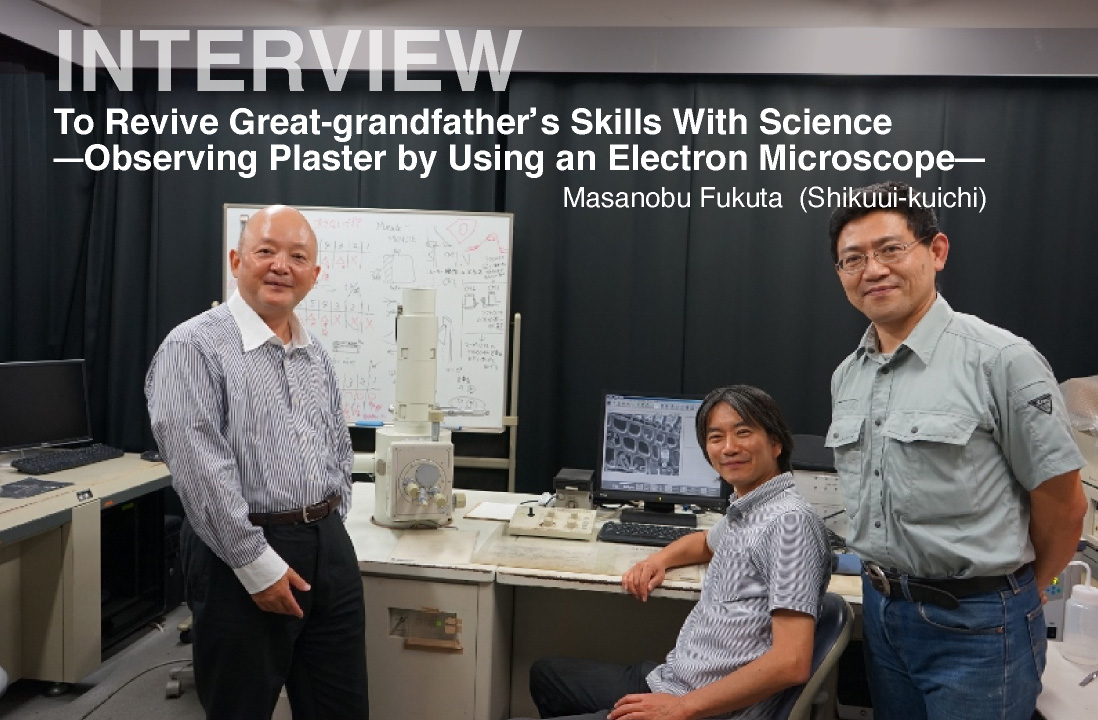

User Interview

―You are the president of the plaster company. Is it a family business?

What I know is that we have been in business since my great-grandfather’s time. It’s not clear when the business started. Our company not only provides plaster but also applies the plaster. In addition, we perform a wide range of other work.

―Did you take over the family business because you were originally interested in plaster?

My major in high school was chemistry, and I had worked as a flight engineer for a company. I think I originally liked manufacturing.

―Why did you make a career change to the plaster company from that of a flight engineer?

Because when I saw my grandfather and father sweating over their work while being considerate of our client’s feelings, I found it was cool. In addition, there is a long distance between manufacturers and consumers in the current social structure, right? Are we conveying how great the products are to our clients as well as we can? Also, are manufacturers aware of our client’s needs? I was starting to question like that.

―Do you mean the quality of plaster is not fully appreciated?

First, let me explain about plaster. Plaster has actually been used since ancient times and was found in the walls of tombs from ancient Egypt. Plaster offers excellent odor and humidity control, in addition to fire protection. Since plaster is made of natural materials, such as limestone, shells, seaweed paste, hemp fibers, and water, incinerating it does not produce harmful substances. However, the annual consumption of plaster is only two billion plus yen. This is equivalent to the sales goal of a new product from major beverage makers.

Products are Made by Manufacturers with Great Effort

―Was everything going well after you took over the family business at the age of 24?

When I first started in the business, I was always undertaking work other than plaster. It included roadwork. But, I found it interesting that plaster did not set well depending on the day, so I started research on combinations. A plaster could do this intuitively. Even the instructions for combinations had not been saved. I have to be able to explain the products with confidence in myself, don’t I? But, this is the same work that my great-grandfather Kuichi was doing.

Encounter of Manufacturing Capability of Nagoya Institute of Technology with the Company That Values Traditional Products

―What made you start using the Nanotechnology Platform?

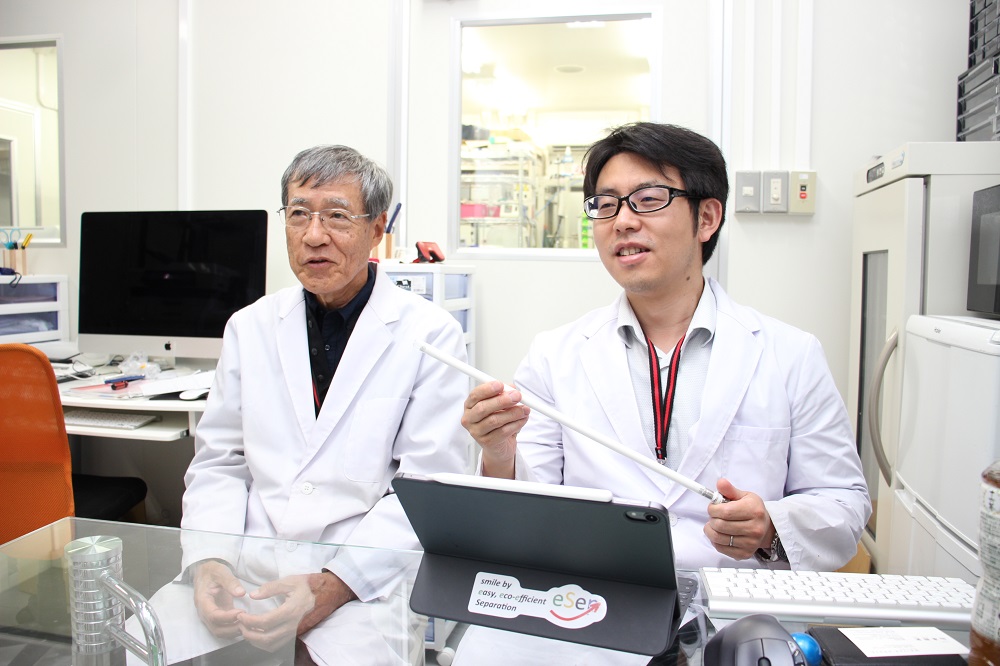

Matsuyama: We had connections to the Chunichi Shinkin Bank and the Japan Science and Technology Agency. So it all started when we looked for motivated small and medium companies. When we met for the first time, they showed me they were trying very hard to burn plaster. They said, “Look! It doesn’t burn, does it?” I was surprised, ha ha.

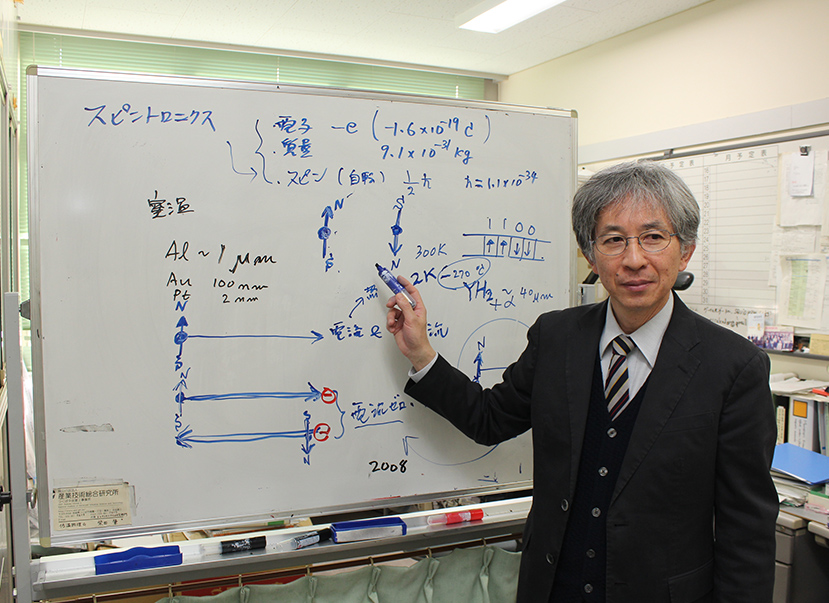

Tanemura: It started with a consultation about analysis of the ingredients and the structure of plaster. No one had ever analyzed things like that. In addition, it was actually pretty difficult to prepare samples for monitoring with the scanning electron microscope (SEM). We focused Nagoya Institute of Technology’s expertise on it.

―How are you utilizing the results from the SEM and ingredient analysis actually?

First, I was personally very surprised by the results. I found a difference in the structure of the plaster made by mixing cedar powder, and it showed a correlation with the characteristics of plaster. This helped us explain it to our clients.

Elucidate the Good Points of Traditional Items from a Scientific Perspective to Spread Them to the World

―Mr. Fukuda, you handle other new materials. What inspires you about the materials?

I love reading old architecture books. Let me give you an example. Milk casein glue, which we aim to spread, was already used in ancient Egypt. Even now, mokkan (wooden tablets on which an official message is written) from those days still stick together. Recently, I began thinking of mixing saffron into plaster. I picked up this idea from old architecture books, which say that the plaster smells good. But, I’m still considering it, ha ha.

―How much of people’s attention are you actually getting?

I believe it is certainly increasing. After the JST fair, we started getting inquiries from trading companies. Also, we received an order of work for a large house. Other than that, we started developing relationships in scientific research, for example we provided materials for collaborative research with colleges.

―When people live in a house with plaster walls, how do they feel?

They really appreciate the house, which allows them to breathe fully and sleep well. We hold the Plaster Salon on the third Saturday of each month, where people are surprised at how comfortable a room with plaster walls is. There are classic records and you can have a pleasant chat over a cup of tea. By all means, please come here, ha ha.

―Finally, let me know your attitudes toward manufacturing.

I hope that I can elucidate the good points of traditional items from a scientific perspective and that I do work, which establishes an emotional bond between manufacturers and clients, like my great-grandfather Kuichi.